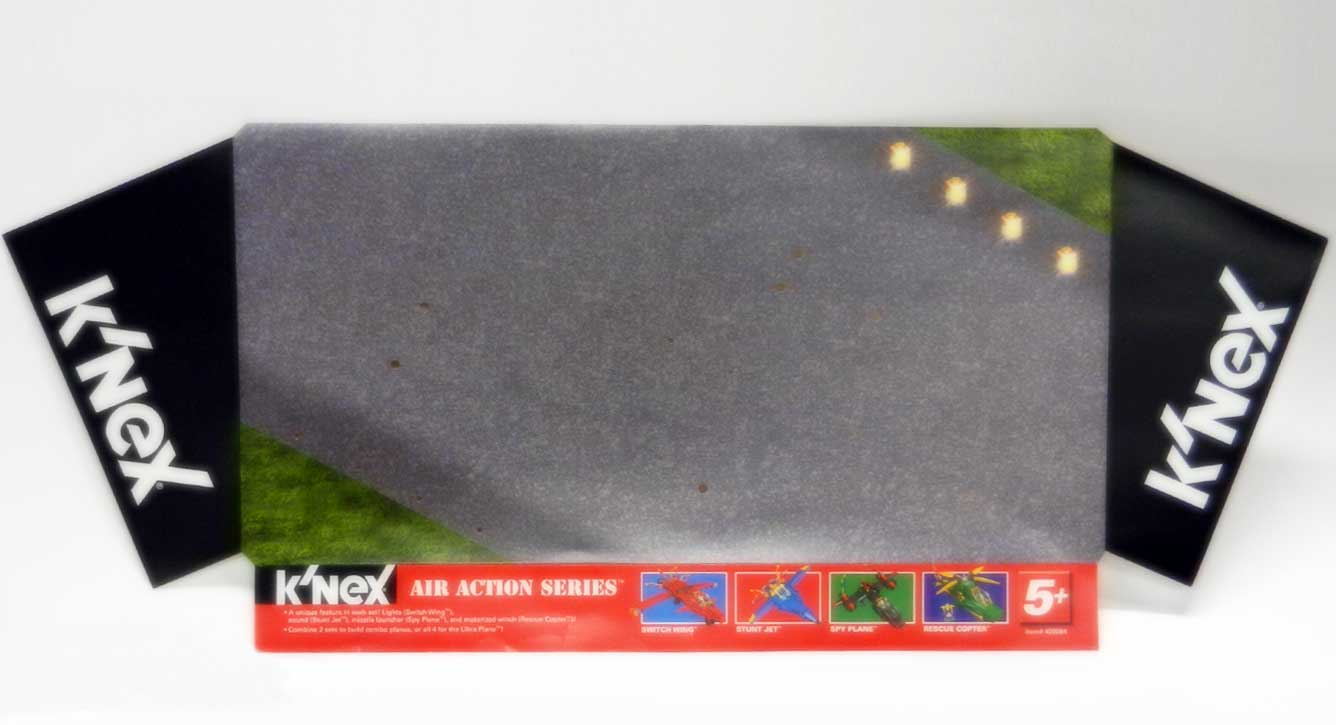

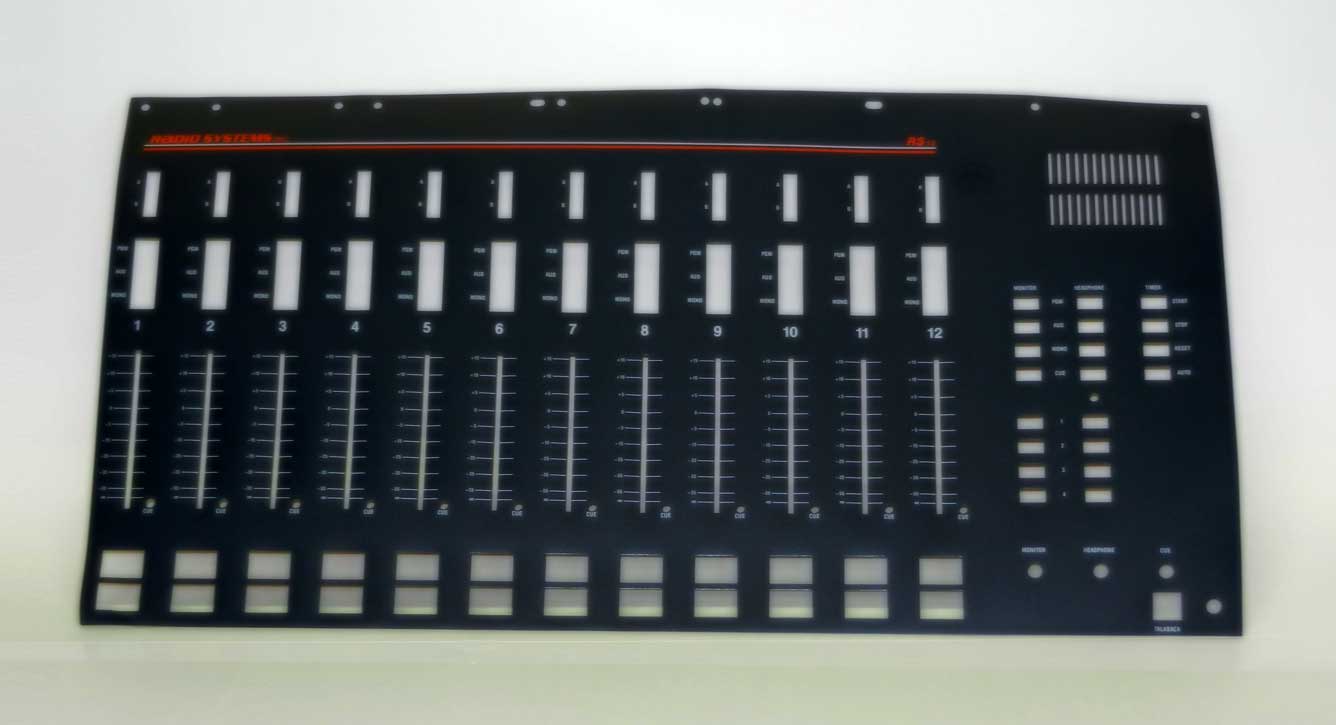

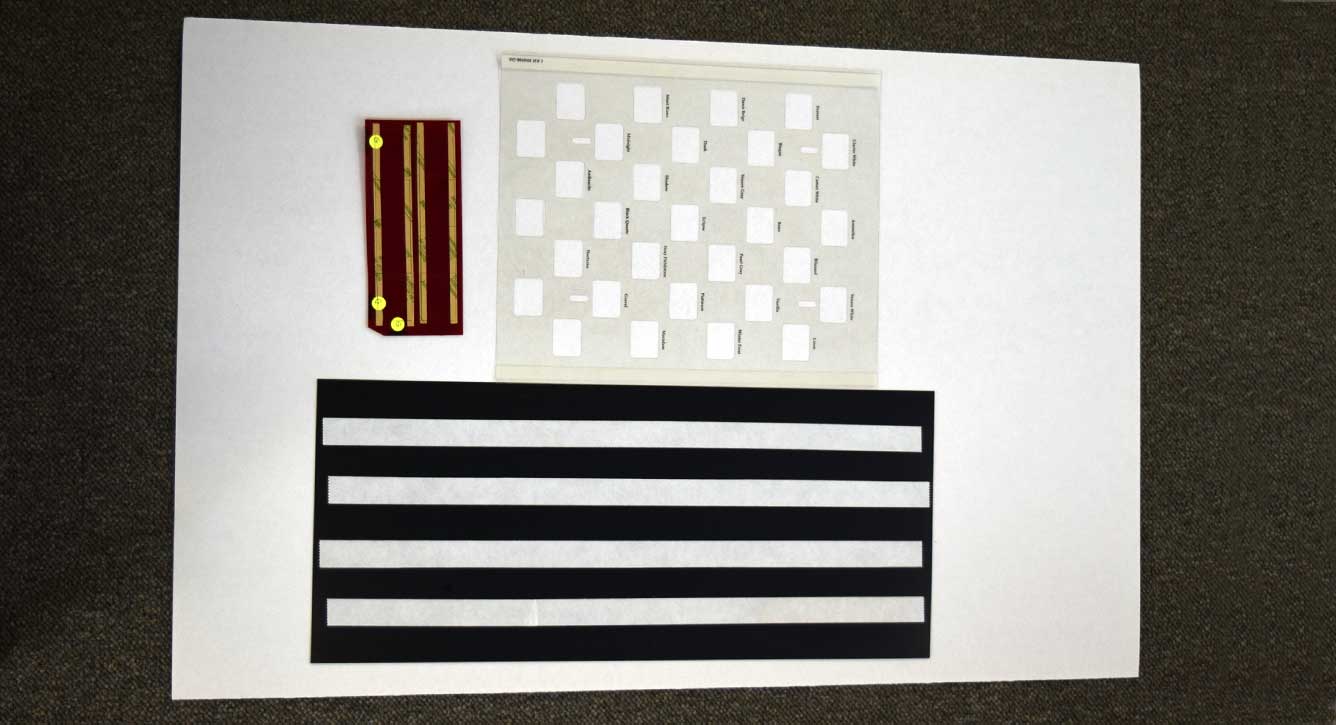

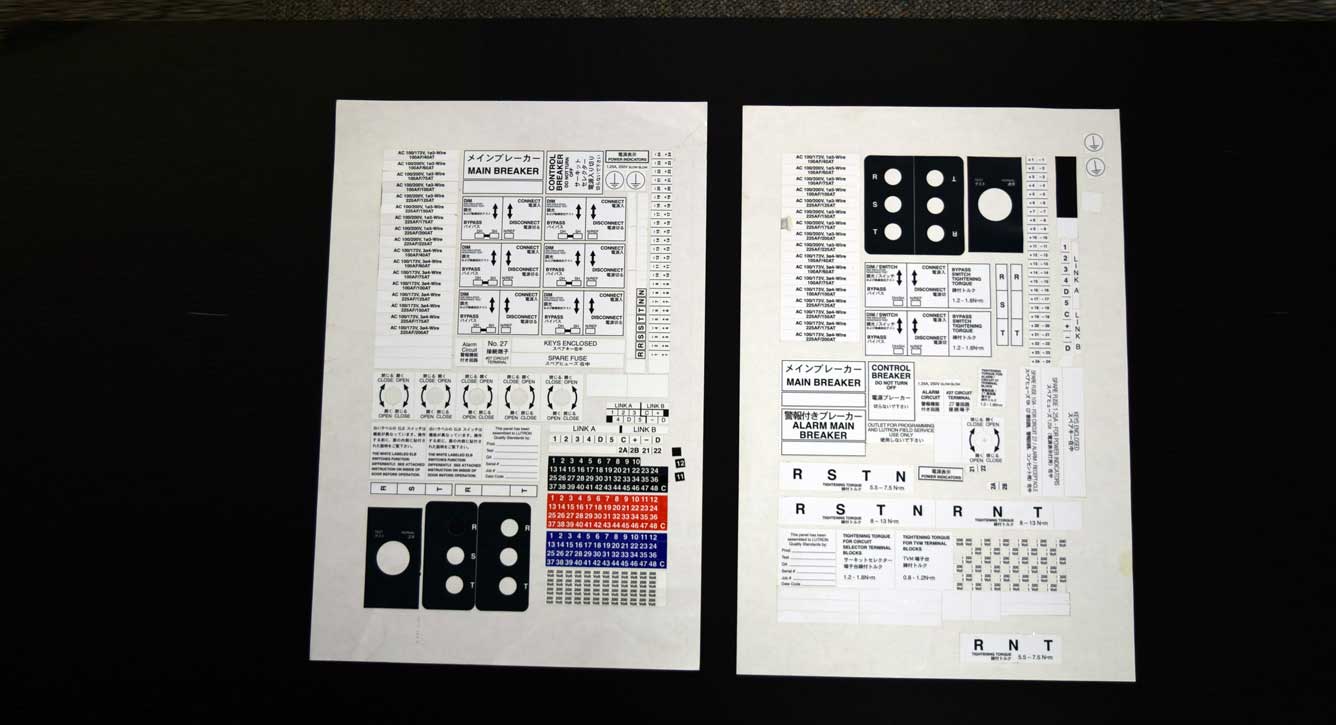

Die Cutting

Acme Specialties, Inc. has the capability to die-cut, crease or kiss cut materials from as thin as .003 film to .125 styrene and expanded PVC through .250 chipboard. We can accommodate the smallest of parts up to a whopping 40" x 56" sheet size. Our staff is knowledgeable to be able to construct your tooling according to the demands of your material or layout. We would be happy to assist you in all aspects of your next project to deliver to you excellent die-cut parts.

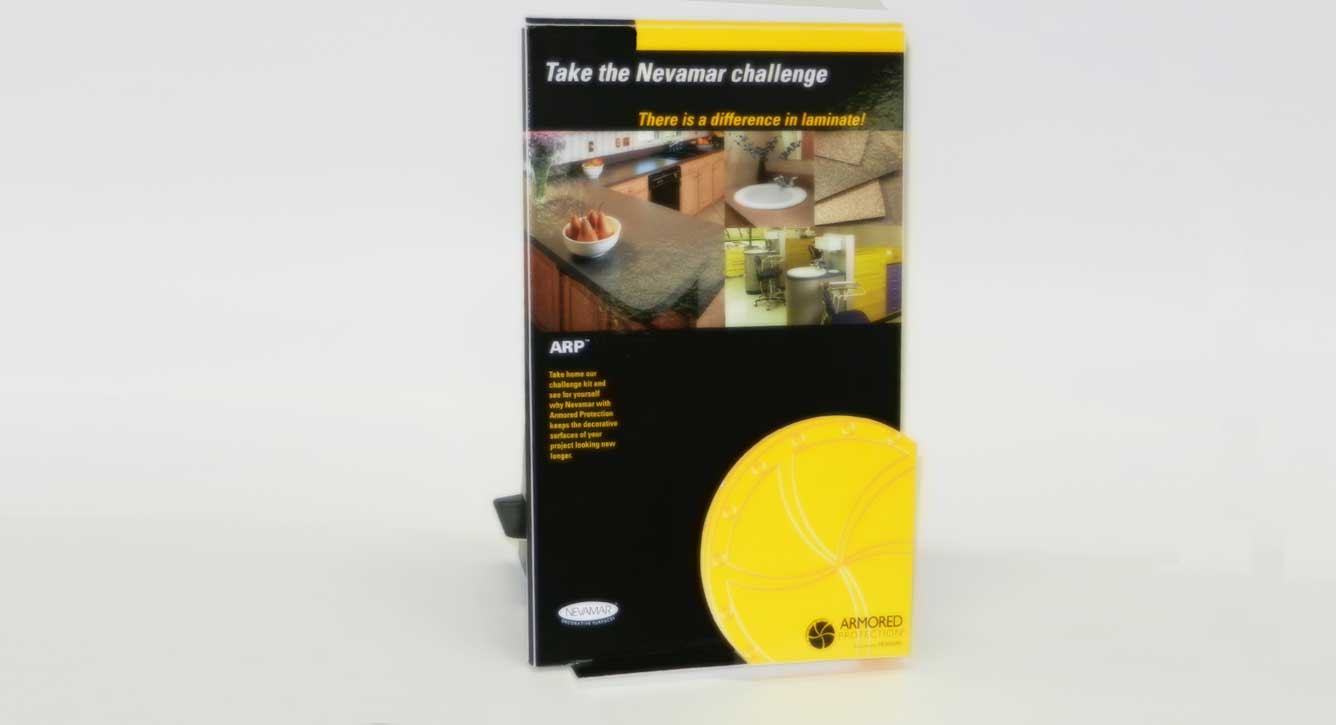

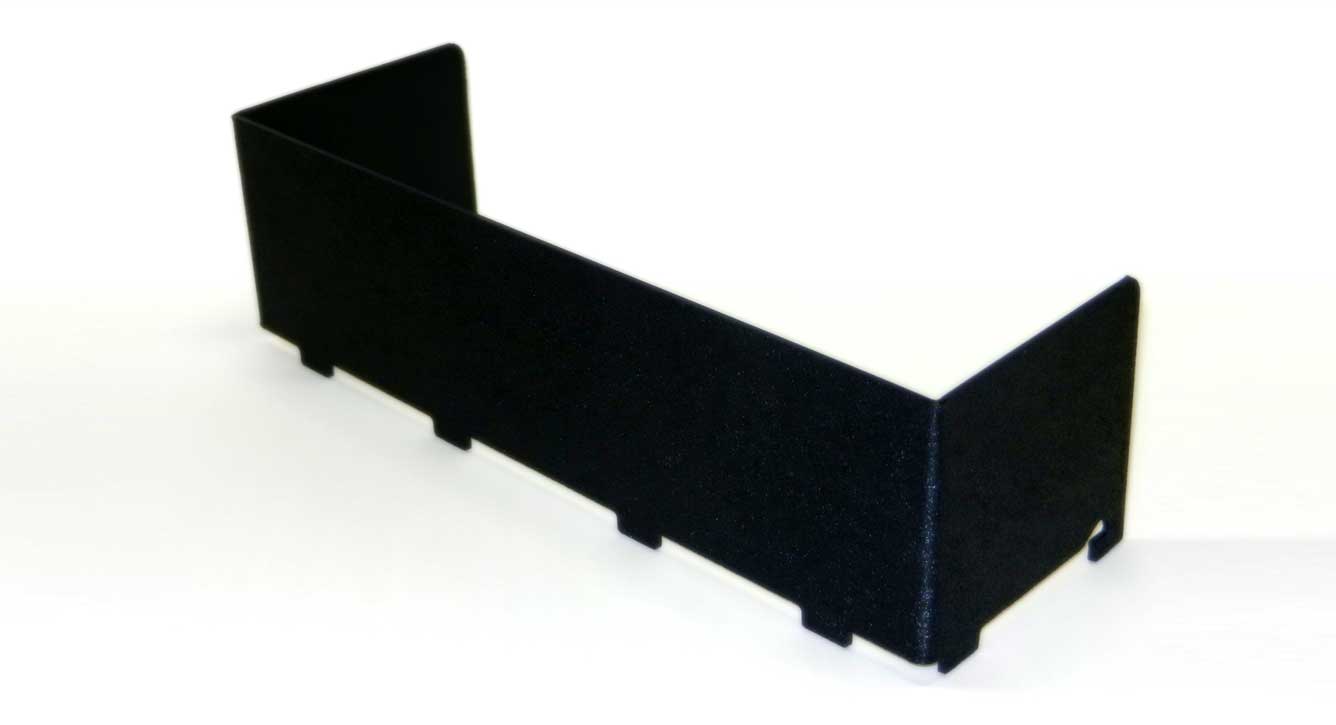

Heat Bending

Acme Specialties, Inc. has been heat bending plastic for over 15 years. We have bent parts made from vinyl, styrene and expanded PVC. We have formed large 1/8" thick display parts to thin 1/16" industrial parts and freezer dividers. If your next display or industrial part requires to be formed, think Acme Specialties, Inc. for your solution.

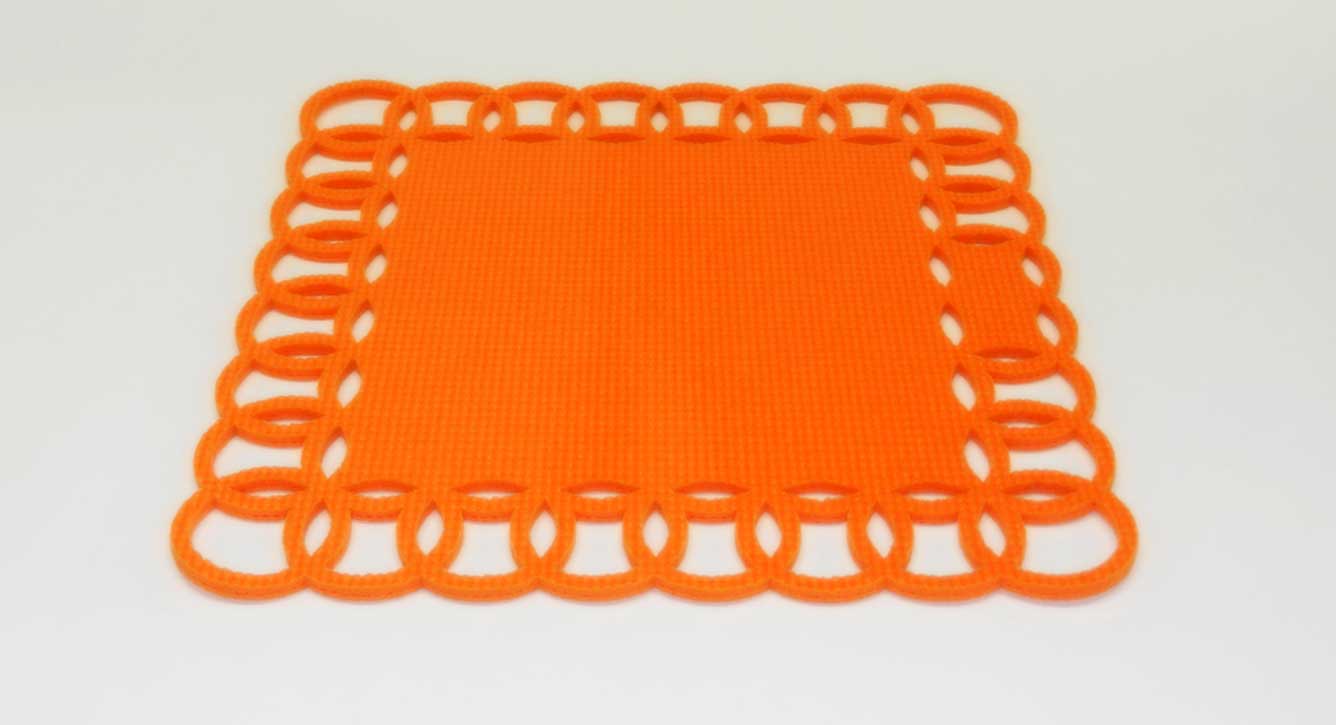

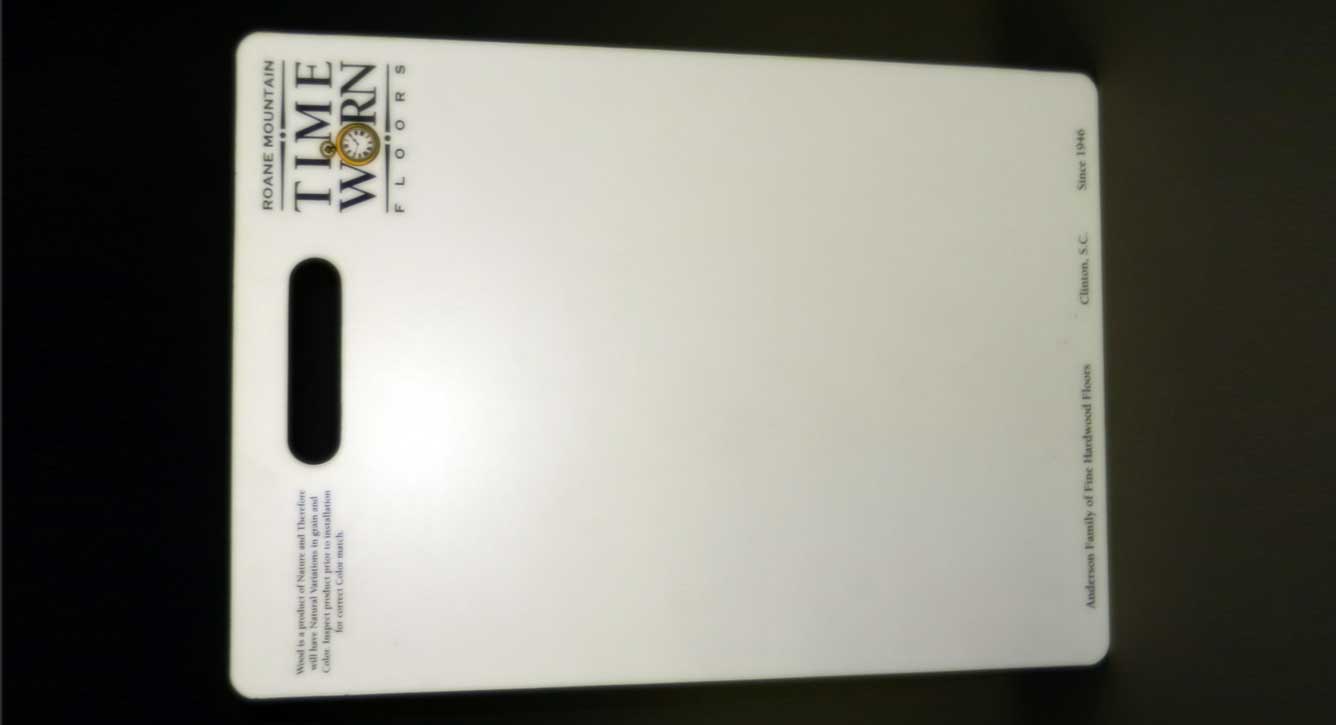

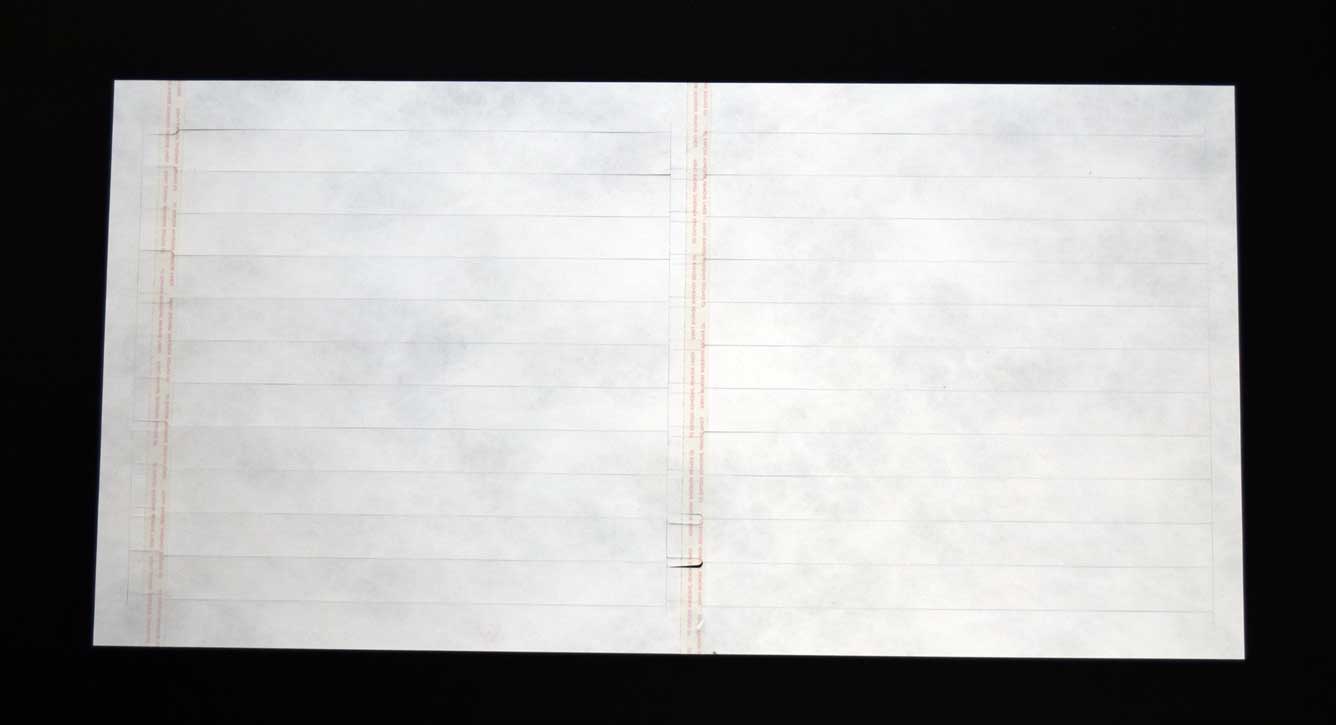

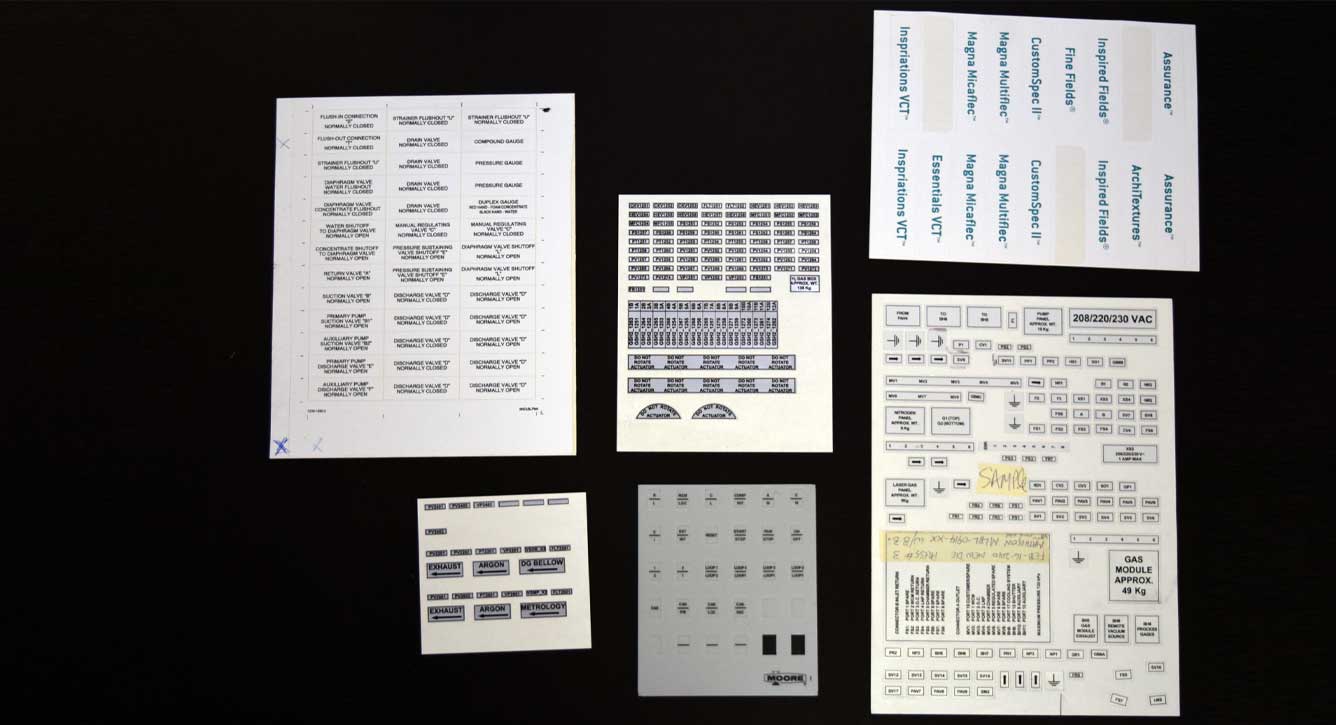

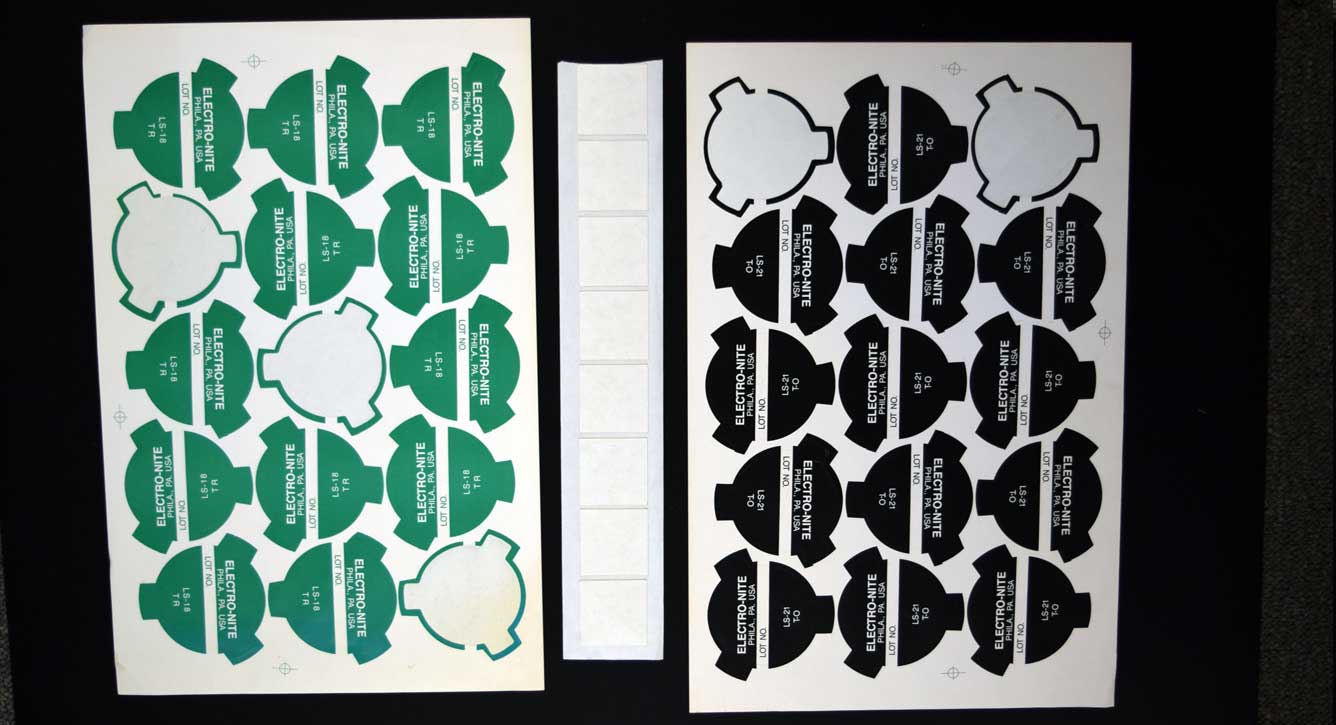

Kiss Cutting

Acme Specialties, Inc. can produce pressure sensitive labels cut to the release liner paper or cut them through. We can create scores in plastic, SBS, or chipboard by limiting the distance the blade cuts into the material. The end result allows you to bend your material with a uniform straight crease. If your labels need to be kiss cut, or your part needs to be bent, Acme Specialties, Inc. can design the tooling and cut your parts accurately.

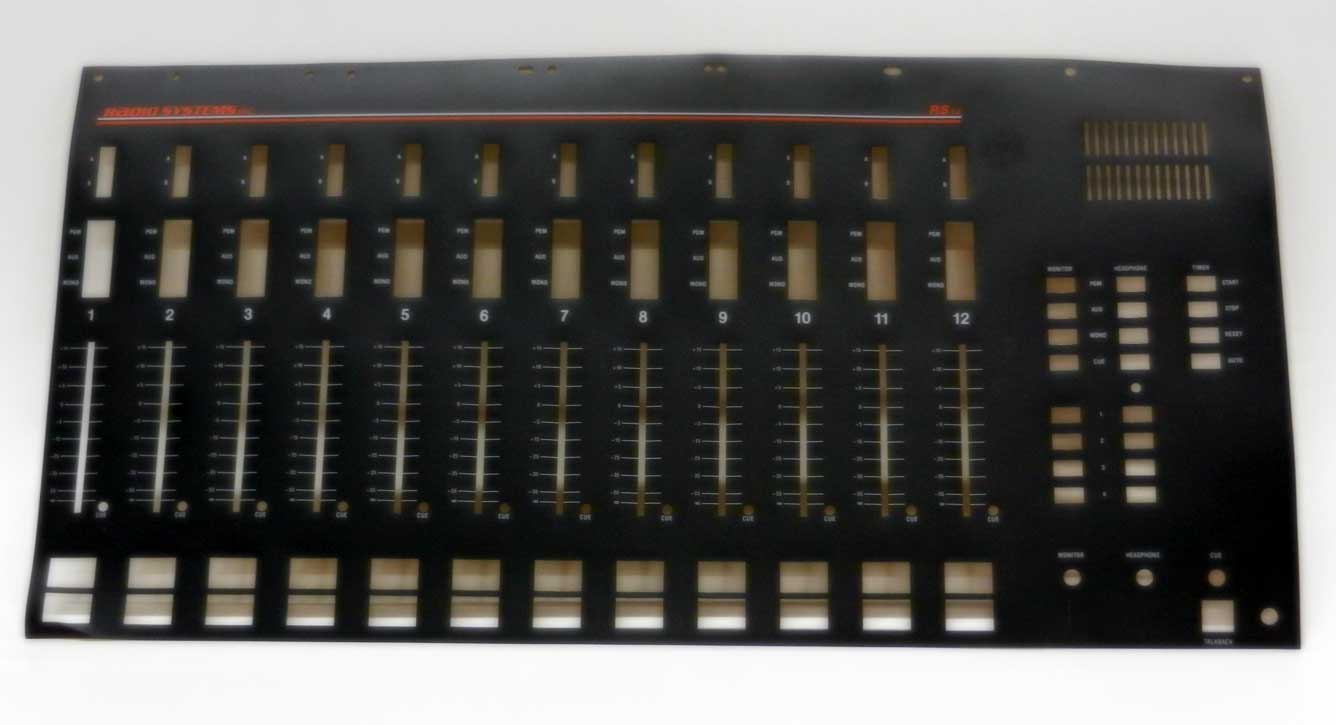

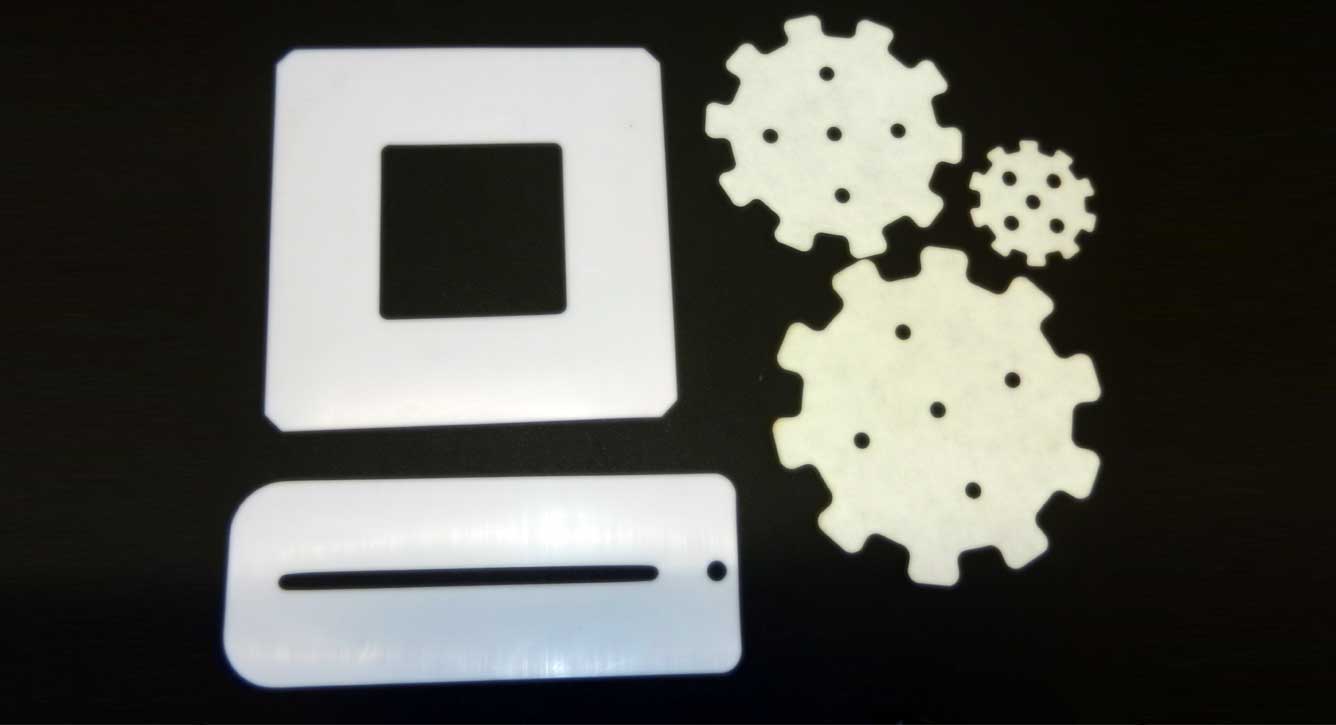

Plastic Stamping

Acme Specialties, Inc. has the capacity to cut your plastic parts with matched metal tooling. If your production run is large, we can roll feed your material to produce economical parts. We can punch thicker material which is not easily cut using standard steel rule dies. Let Acme Specialties, Inc. quote your next stamping or punching project.

Taping & Transfer Adhesives

If your part needs pressure sensitive material to be applied, Acme Specialties, Inc. can help. We have the capability to apply pressure sensitive tape strips of ½", ¾" and 1" in width to most materials. We can also back your part with full pressure sensitive material up to 36" in width. Send us your printed part, we will apply pressure sensitive adhesive to the back, die-cut, and deliver a perfect part.